概述

铸铝加热器经精加工后它能和被加热体紧密贴合。其使用温度一般在摄氏150~450度之间,可广泛应用于塑料机械、模头、电缆机械、化工、橡胶、石油等设备上。是以管状电热元件为发热体,并弯曲成型,用优质铸材料为外壳,外壳以离心式浇铸成各种形状的电加热器,有圆型、平板、直角型、风冷、水冷及其它异型等。

技术特性

1.铸铝加热器表面负荷可达到2.5-4.5w/cm2,最高工作温度300-450℃之间;

2.铸铝加热器是一种高效热分部均匀的加热器,热导性极佳的金属合金,确保热面温度均匀,消除了设备的热点及冷点。具有长寿命、保温性能好、机械性能强、耐腐蚀、抗磁场等优点。将外散热面增加保温装置,内散热面烧结红外线这样可节约用电35%。

应用范围

主要用于塑料工业注塑机、挤出机和吹塑机的加热,同时也可用于反应釜、熔体管道等化工领域的加热。

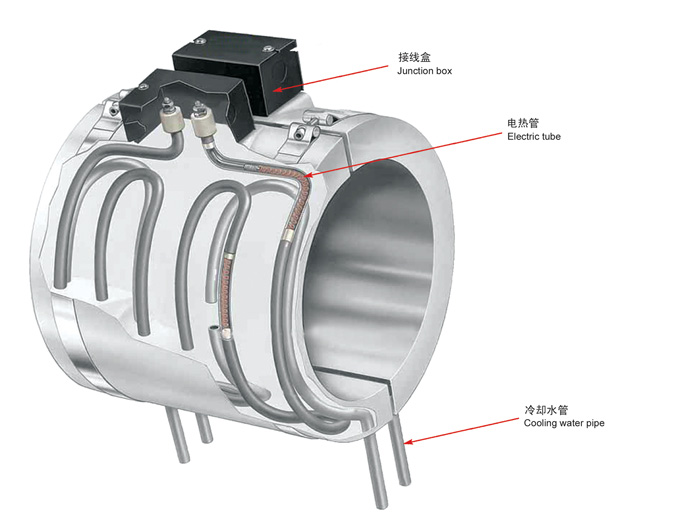

产品结构

采用电加热管,浇铸在铝或铜等金属材料中,加热丝与空气隔绝,加热体坚固耐用,加热均匀,热交换迅速,可在加热体内设置冷却水道或风道。特殊环境中采用防爆接线盒,如需保温,则配置保温层。

技术参数

铸铝工作温度可达350℃,功率密度可高至3.5W/cm2。

铸铜工作温度可达650℃,功率密度可高至8W/cm2。

Application

It is mainly applied to heating the plastic injection molding machine, extrusion machine and blowing machine. Meantime, it also can be used to heat reaction kettle, melt pipe, etc in chemical industry.

Structure

The electric heating tube is adopted with its heating strip casted inside the metal material such as aluminum or copper and isolated from the air. The heating body is tough and durable, which heats evenly and exchanges heat very fast. Cooling water or air duct could be set up inside the heating body for option. In particular environment, we use anti-explosion junction box. If thermal preservation is needed, we shall add insulation layer.

Technical parameter

The working temperature and the power density of cast aluminum are respectively up to 350℃℃ and 3.5W/cm2.

These of cast copper are 650℃℃ and 8W/cm2.

铸铜加热器概述

铸铜加热器特点具有长寿命、保温性能好、机械性能强、耐腐蚀、抗磁场等优点。是以管状电热元件为发热体,用优质铜铸材料为外壳经压铸成型的电加热器,其使用温度一般在摄氏150~600度之间,防爆加热器防爆标志为ExdⅡBT4 ExDⅡBT6 ExdeⅡCT6等.广泛应用于塑料机械、模具、电缆机械、合金压铸机、管道、化工、橡胶、石油等设备。

使用说明

1.应放在干燥处、若因长期放置,绝缘电阻低于1MΩ时,可在摄氏200度左右的烘箱中烘烤5-6小时,即可恢复正常。

2.工作电压不得超过额定值的10%;

3.接线部分放在加热层、保温层以外,外壳应有效接地;

铸铜加热器使用注意事项

1.铸铜加热器应做好定位固定,有效发热区必须与受热体紧密贴合,严禁空烧。发现表面有灰尘或污染物时,应及时清除干净再用,以免影晌散热而缩短使用寿命。

2.电热管出线端的氧化镁粉,在使用场所避免受到污染物与水分渗入,防止漏电事故的发生。

3.工作电压不得超过额定值的10%;空气相对湿度不大于95%,无爆炸性和腐蚀性气体。

4.接线部分放在加热层、保温层以外,外壳应有效接地;避免与腐蚀性、爆炸性介质、水份接触;引接线应能长期承受接线部分的温度及加热负载,接线螺丝紧固时应避免用力过猛。

5.铸铜电加热圈应放在干燥处、若因长期放置,绝缘电阻低于1MΩ时,可在摄氏200度左右的烘箱中烘烤5-6小时,即可恢复正常。或降低电压通电加热,直至恢复绝缘电阻。

加热器的选型

目前市场上提供多种加热器配置。用于塑料机械料筒加热的有三类常见加热器:云母、陶瓷关节及金属铸造加热器。

一、云母加热器:

云母加热圈大约厚5mm,能适应多种几何形状和特殊部件,如孔和凹槽,但云母用于加热器绝缘层时,云母温度不应超过550℃。当温度超过该水平,粘合剂就开始退化,绝缘强度也将变弱,因此加热器的护套温度不能超过450℃。以及云母加热器的标准功率密度只有3W/cm2。目前云母加热器已很难满足越来越多塑料工艺的要求。

二、陶瓷加热器:

陶瓷具有耐高温绝缘性,因此陶瓷加热器可处理760℃的温度。陶瓷加热器的柔软可形成各种加热器直径。遗憾的是,陶瓷的优点也是其弱点,由于它能存储元件金属丝产生的热量,因此人们很难控制陶瓷加热器的温度。这会导致不必要的废料,在塑料生产工艺的较早阶段,这一点尤其突出。另外,陶瓷加热器在拆装过程中容易损坏,特别是升温以后,加热器会变得比较松散,给安装带来不便。陶瓷加热器不能受到污染这一特性也限止了这类加热器的应用范围。

三、 金属铸造加热器:

金属铸造加热器是将一定形状的加热管浇铸在铜、铝或铁等材料中,这类加热器体积较大,制作成本高,生产过程中能耗高,对环境有污染,以及使用时热效率较低,国外已较少采用此类加热器(除非特定要求)。

四、新型氧化镁绝缘加热圈

氧化镁绝缘加热圈是一种高性能的加热器,采用导热性能比传统的云母和陶瓷更高的高纯氧化镁作为绝缘材料,一层薄薄的致密的氧化镁填充在电热丝与金属外套之间,电热丝的热量迅速传递给被加热物体,降低了电热丝的温度,大大的提高了加热器的使用寿命。氧化镁的耐高温性和压缩层具有卓越的导热性能和绝缘强度,氧化镁绝缘加热圈的功率密度达到15W/cm2,使用温度可达760℃,利用该性能可制造高效加热器以适应现代的塑料制造工艺。

考虑加热器类型时,必须了解每种类型加热器的性能和局限。零件的几何形状、温度和加热时间要求确定机器所需加热器的类型。

每个类型加热器都具有与众不同的特点。当加热器加热零件时,由内部绝缘体提供必要的绝缘强度,所以区分这些加热器的唯一材料是内部绝缘体。每个加热器中的绝缘体对加热器的寿命和性能具有重要影响。

现代塑料加工工艺对加热器的要求会更高,对温度的均匀性、热反应性能、特殊材料所需的高温要求以及倍受关注的热效率,氧化镁绝缘加热器因其出色导热性能和绝缘强度,在加热器市场一定会占显著地位。

Currently on the market offers a variety of heater configurations. There are three common types of heaters: mica, ceramic joints and metal casting heater for plastic machinery barrel heating.

●Mica heater:

Mica heating coil about the thickness of 5mm, can adapt to a variety of geometric shapes and special parts, such as holes and grooves, but mica for the heater insulating layer, mica temperature should not exceed 550℃. When the temperature exceeds this level, the adhesive begins to degenerate, the insulation strength is becoming weaker, so the heater sheath temperature must not exceed 450 ℃. Mica heater standard power density 3W/cm2. The mica heater has been difficult to meet the requirements of more and more plastic process.

●The ceramic heater:

Because of the high temperature ceramic insulation, the ceramic heater can be processed to a temperature of 760℃. The. The soft ceramic heater may be formed various heaters diameter. Unfortunately, the advantages of the ceramic is also its weakness, due to the heat generated can store element wire, so it is difficult to control the temperature of the ceramic heater. This causes unnecessary waste, in plastic an earlier stage of the production process, which is particularly prominent. In addition, the ceramic heater is easy to damage during disassembly, especially after the temperature, the heater will become more loose, to install the inconvenience. The ceramic heater of this feature can not be contaminated and also limiting the scope of application of such a heater.

●The metal casting heater:

Is a certain shape of the heating tube cast in copper, aluminum or iron material, this type of heater sizes, high production costs, high energy consumption in the production process, the pollution of the environment, as well as a lower thermal efficiency in the use of foreign been less used to this type of heater (unless a specific request).

●The new magnesium oxide insulated heating coil:

Magnesium oxide insulated heating coil is a high performance heater, thermal conductivity than the traditional mica and ceramic higher purity magnesium oxide as the insulating material, a thin layer of dense magnesium oxide filled in electric wire and metal jacket between the heat of the heating wire quickly passed to the object to be heated, reducing the temperature of the heating wire, greatly improve the life of the heater. Magnesium oxide of high temperature and compression layer has excellent thermal conductivity and dielectric strength, magnesium oxide insulated heating coil power density 15W/cm2 use temperatures up to 760℃, the use of the performance can be manufactured efficient heater to adapt to the modern plastic manufacturing process.

Considering the type of heater, you must understand the performance and limitations of each type of heater. Part geometry, temperature and heating time required to determine the type of machine desired heater.

Each type heater has distinctive features. When heated by a heater parts, by the internal insulator to provide the necessary dielectric strength, so the only material to distinguish these heater internal insulator. The insulator of each heater has an important impact on the life and performance of the heater.

Modern Plastics Processing and process requirements of the heater will be higher, temperature uniformity, thermal reaction performance, high temperature requirements of special materials required, and the thermal efficiency of a well-focused, magnesium oxide insulation heater because of its excellent thermal conductivity and dielectric strength will figure prominently in the heater market.